- ****Plan accordingly to receive items when you need them. ALL "Made to Order" items with lead times will effect the entire order fulfillment timeline. Custom items are NOT mass produced and require fabrication time. Orders will ONLY ship out in their entirety. If you need standard items shipped sooner, place multiple orders.****

- .

We have updated the SPACER and is now thinner than the older style. All new orders will have 0.0625" Thick Spacers. If you need an OLD 0.09375" Thick Spacer please contact us.

Install Tip and Advise:

*****With the bearing kit installed it is very possible with very fine grain powder and near full casings to still have powder spillage but nowhere near what you would get without one installed. A quick install and tightness tip would be: The shellplate nut should be tight enough to where the index pawl "has to" cycle the shellplate into position 100% and "does not" allow the index ball to snap the plate into position. So basically the operator's upward stroke determines the speed and harshness of the indexing. Most powder spillage is due to the plate snapping into position towards the end of the stroke by the index ball.

There are too many other variables such as vibration, case-to-shellplate fitment, case fill percentages for each powder, powder cop pulling powder out of casings etc that the bearing nor any other mechanism could possibly eliminate powder spillage 100%.*****

This Kit is to improve indexing on the Dillon 1050 and extremely reduce powder spillage from the shellplate "snapping" into position. Delrin(DuPont) Bearing will always be our number one choice as it is designed to take the abuse and not abuse the shellplate. Any material harder than the shellplate will end up "grooving" the shellplate on the bottom, making a nice "ring" like a "fuller" in a knife blade. Made in USA.

Since we are unable to verify each end user's press condition and install capabilities, etc. we are not responsible for any damage to our product whatsoever.

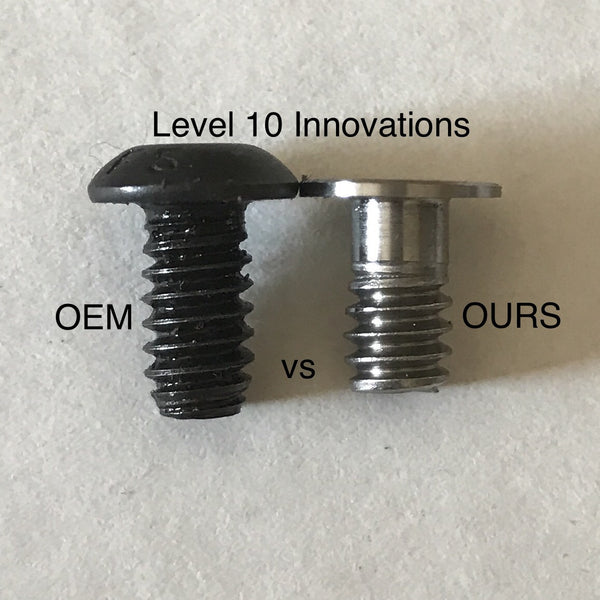

Below Depicts the Bearing Kit with Optional Retaining Screws

NEED MORE ROOM THEN YOU WILL NEED THE SPACER....

****NOW AVAILABLE WITH TOOLHEAD SPACER, this eliminates the Toolhead bottoming out on some RL and XL presses' shellplate retaining screw heads. Some presses have tighter tolerances than others as no two presses are exactly alike. NO NEED TO MACHINE/MODIFY SHELLPLATE NUT!

SPACERS are made to order, please allow up to 7-10 business days to ship.

All dies and primer system push rod must be adjusted for the additional height.

SPACER KIT FEATURES

- Eliminate toolhead from hitting the shellplate nut's retaining screw heads allowing 100% complete stroke

- Casefeed cam still manipulates plunger 100%

- Precision ground, through hardened steel for precise fit and durability.

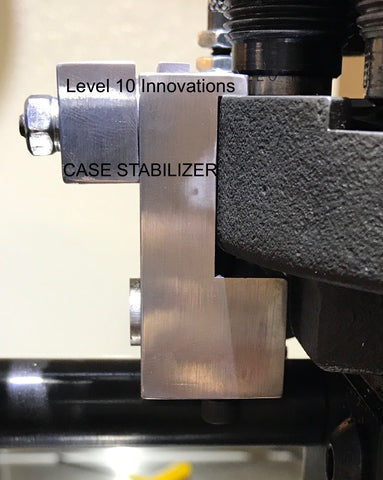

Picture Below shows a Super 1050 that DOES NOT need the spacer but illustrates the cam still functions 100%.